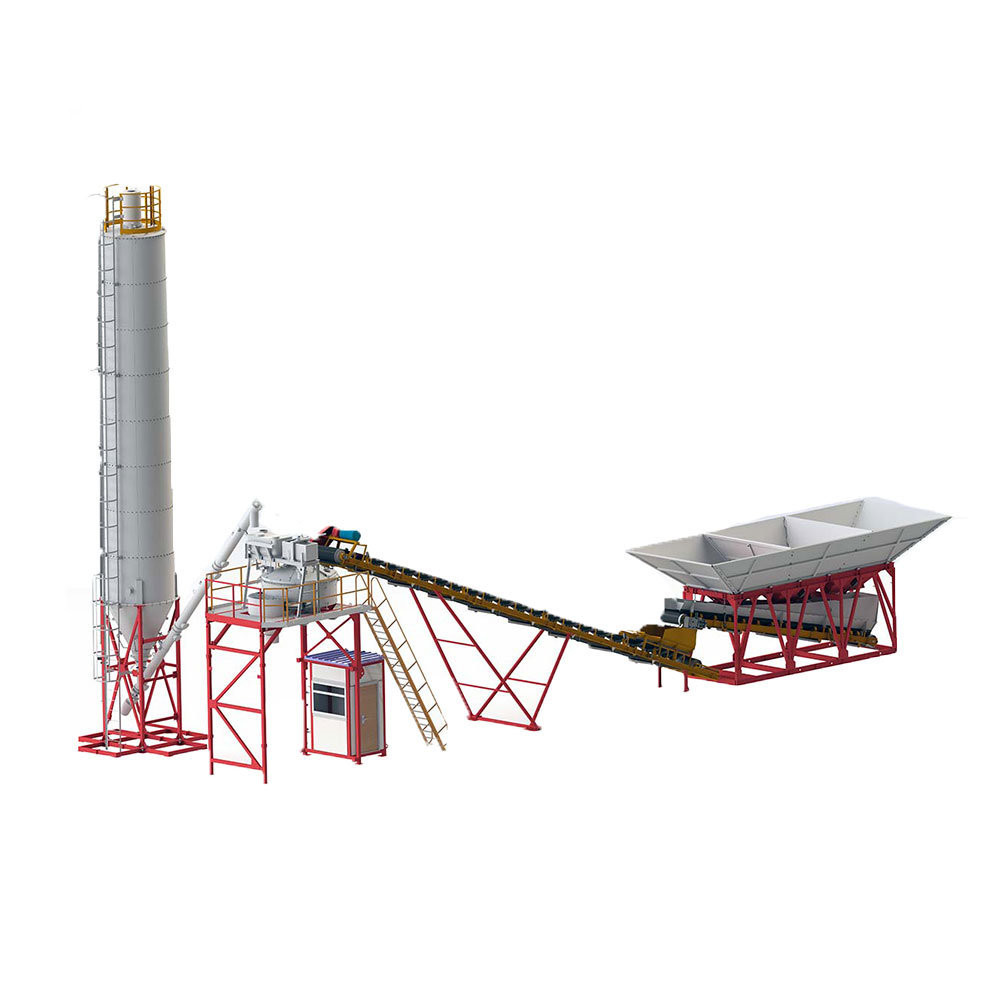

Stationary Fixed Batching Plant, Ready Mixed Concrete Batching Plant

Stationary Fixed Batching Plant, Ready Mixed Concrete Batching Plant

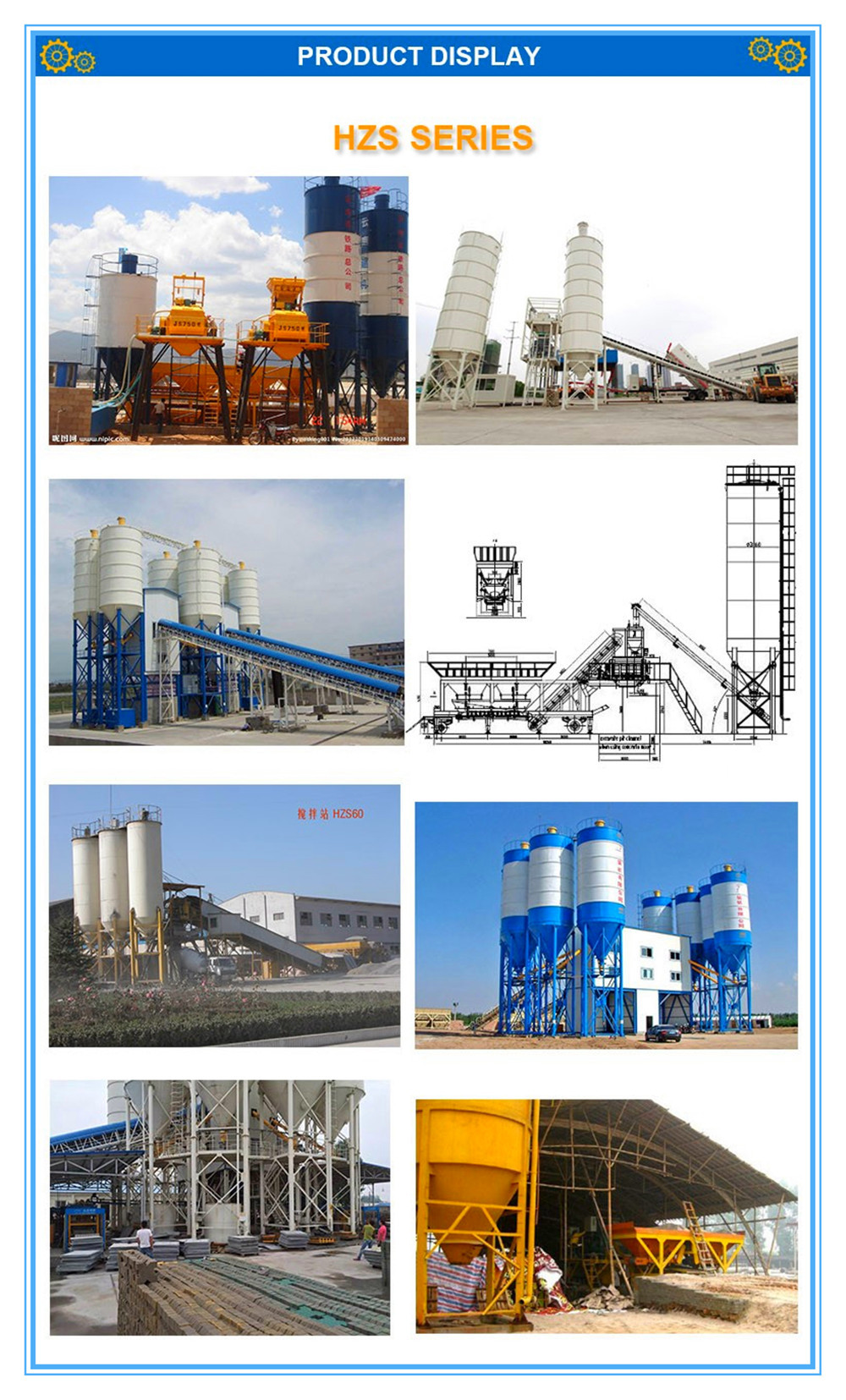

HZS series concrete batching plant belongs to compulsory and efficiency equipment, It includes JS concrete mixer, PLD batching machine,cement silo and control system. The main machine of this series use JS series double shaft compulsory mixer. It is widely used large and medium scale building works, road and bridge works and concrete products prefabrication plants, and is an ideal equipment to produce commercial used concrete.

Concrete batching plant is highly mechanized and automated, with convenient installation and high production efficiency. Excellent manufacturers can guarantee the quality of concrete and save customers a lot of cement or concrete.

Model | HZS25 |

Capacity | 25m3/h |

Twin Shaft Mixer Model | JS500 |

Mixer Capacity | 0.5m³ |

Aggregate storage hopper volume | 3m³x 3 |

Max. Aggregate Size (broken stone/pebble) | 60/80mm |

Loading Type of Aggregate to the Mixer | Skip Hopper |

Aggregate Weighing | 1500kg ±2% |

Cement Weighing | 450kg ±1% |

Water Weighing | 300kg ±1% |

Additive Weighing | 30kg ±1% |

Control System | Full-automatic PLC+PC control |

Discharging Height | 3800mm (for customers choice) |

Total Power | 60kW |

Total Weight (approximate) | 15Tons |

Overall Dimension (at work)(L×W×H) | 21400×11500×16510mm |

Cement Silo (optional) | Welded Type, 50Ton*1 |

Power (customized) | 380V/50Hz/3 Phase |

Model | Max. output | Mixer model | Batching plant model | Discharging height | Working cycle time | Weighing accuracy | Dimention (mm) | ||

HZS25 | 25 m³/h | JS500 | PLD800 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 15100*8000*17245 |

HZS35 | 35 m³/h | JS750 | PLD1200 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 15000*12500*17245 |

HZS50 | 50 m³/h | JS1000 | PLD1600 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 32201*16000*17245 |

HZS60 | 60 m³/h | JS1000 | PLD1600 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 42580*22800*16430 |

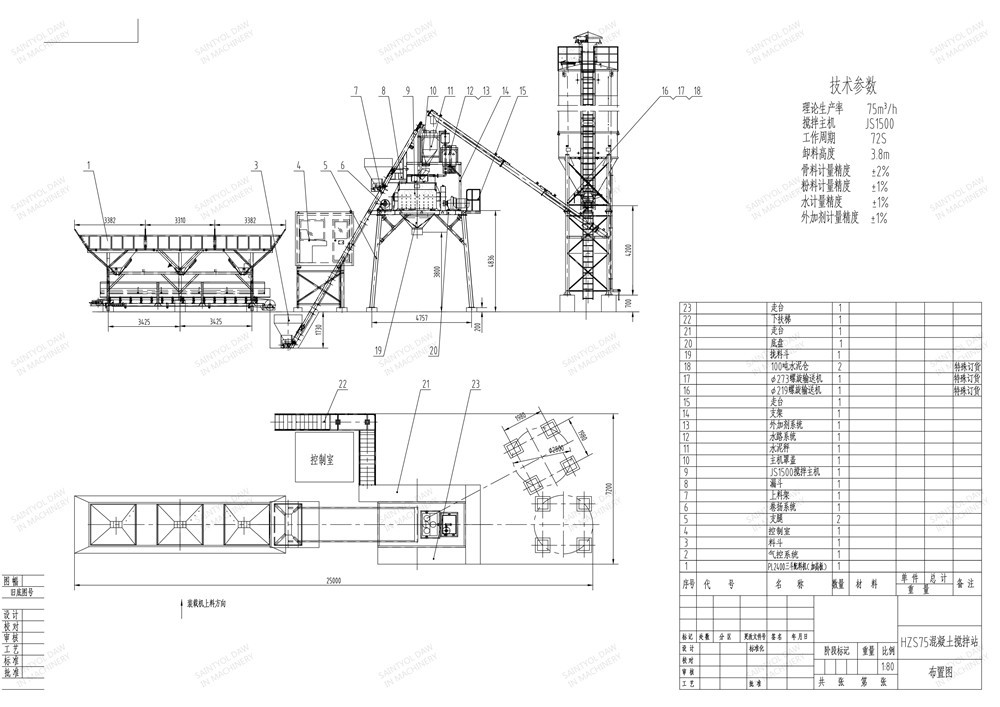

HZS75 | 75 m³/h | JS1500 | PLD2400 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 33091*16835*17245 |

HZS90 | 90-100 m³/h | JS1500 | PLD2400 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 58555*12376*18704 |

HZS120 | 120 m³/h | JS2000 | PLD3200 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 58555*12376*18704 |

HZS180 | 180 m³/h | JS3000 | PLD4800 | 3800 mm | 72 s | Aggregate ±2% | Cement ±1% | Water / Additive ±1% | 60120*13700*18704 |

- Tel

- *Title

- *Content

Don't forget to sign up!

Find out early about all upcoming promotions and

newproducts releases

- Name:

- Michael Liu

- Tel:

0086-186-69798625

0086-532-89659612

- WhatsApp:

- https://wa.me/8618669798625

- Address:

- Office: 216# THE 308 STATE ROAD, CHENGYANG DISTRICT, QINGDAO SHANDONG,CHINA. Factory: No.413# Tieqishan Road, Yuhuangling Industrial Park, Chengyang District, Qingdao, China