Saintyol DAWIN Concrete Pumps: Breaking the Mold with Ultra-High Pressure Technology, Empowering Engineering at its Pinnacle with Customized Services

In the construction engineering field, concrete pumping has always been a core element determining construction schedule and quality. High-rise building pouring faces challenges such as insufficient or unstable concrete delivery, unsuitable equipment leading to inefficiencies in special working conditions, and large-scale projects with low tolerance for error and stringent requirements—Qingdao SAINTYOL DAWIN MACHINERY concrete pumps have already provided perfect solutions to these pain points. With its leading high-rise pumping technology, customized full-process services, and a proven track record of large-scale projects worldwide, SAINTYOL DAWIN MACHINERY has become the trusted choice for countless engineers.

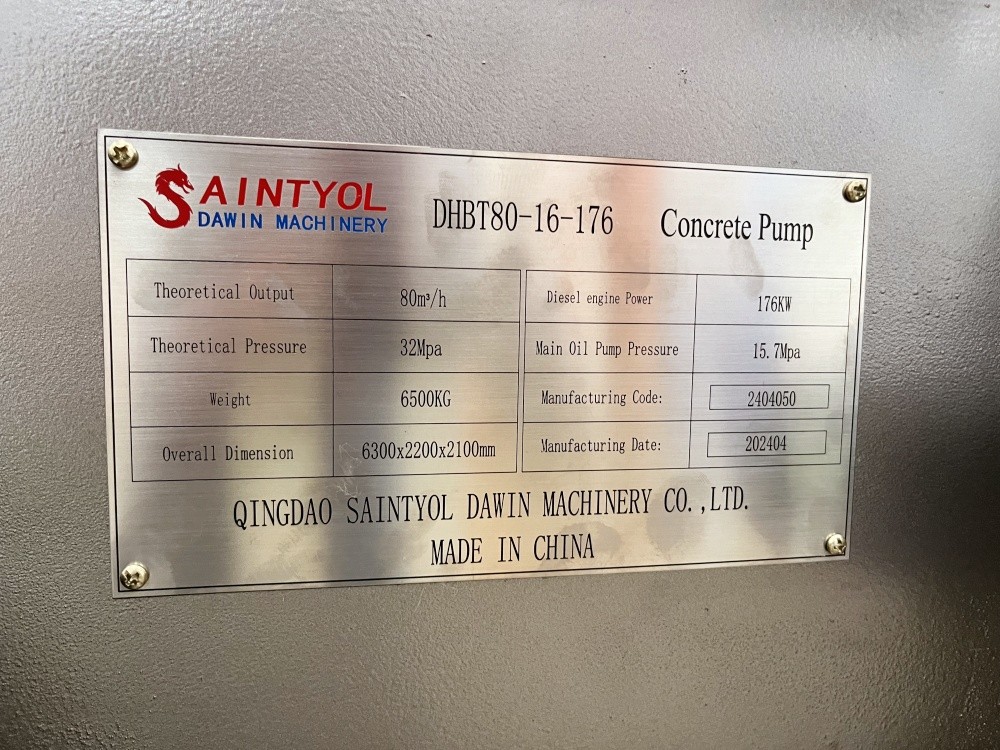

I. Breakthrough in Ultra-High Pressure Technology: Enabling Concrete to Compete in a "Vertical Marathon" Pumping concrete in ultra-high-rise buildings is like making concrete complete an extreme "vertical marathon." For every meter the height increases, pressure loss, the risk of pipe blockage, and the probability of concrete segregation rise sharply. Traditional equipment often struggles at heights above 200 meters, but SAINTYOL DAWIN MACHINERY has easily solved this industry challenge through three core technological innovations. Firstly, the ultra-high pressure power core provides a solid foundation. Equipped with a high-performance hydraulic system synchronized with European technology, the outlet pressure can reach over 28 MPa. Combined with staged pressurization technology, it can easily overcome the conveying resistance at heights of hundreds of meters, achieving stable "one-pump-to-the-top" concrete delivery. The fully hydraulically controlled reversing technology, combined with spectacle plates and cutting rings made of ultra-hard wear-resistant alloy material, not only improves conveying stability but also extends the lifespan of vulnerable parts to an industry-leading level, significantly reducing the frequency and cost of high-altitude maintenance.

Secondly, the intelligent anti-blockage system eliminates hidden dangers. Pipe blockage is the "number one enemy" of ultra-high-rise pumping. SAINTYOL DAWIN MACHINERY has innovatively created a "prevention + cleaning" dual mechanism: the equipment is equipped with a one-button reverse operation function. Once the feed inlet is blocked by large aggregate particles, hydraulic power can be used to quickly break up the aggregate arch, allowing the concrete to flow back and be re-transported after mixing; after pumping, forced high-pressure water flushing combined with chiseling technology thoroughly removes residual concrete from the pipeline. In addition, the modular valve cavity design allows for quick disassembly and unblocking even stubborn blockages.

Thirdly, precise process control ensures quality. The intelligent electronic control system monitors the equipment's operating status in real time, automatically adjusting pressure and flow to ensure uniform concrete filling without segregation. At the same time, the pipeline layout is optimized, and special pipe clamps are pre-embedded with standard tooling to effectively solve the problems of grout leakage and air leakage under high-pressure conditions, achieving "zero sealing accidents" in ultra-long-distance pumping, laying a solid foundation for the quality of ultra-high-rise buildings.

II. Customized Service Upgrade: Rejecting a "one-size-fits-all" approach, adapting to every working condition. Engineering scenarios vary greatly. Urban core areas require environmentally friendly and quiet environments, while remote mountainous areas lack power and network access. Tunnel construction spaces are confined, and chemical industrial parks pose corrosion risks—standardized equipment inevitably faces challenges in adapting to different environments. SAINTYOL DAWIN MACHINERY understands this well, creating a customized service system covering the entire chain of "research-design-commissioning-operation and maintenance," ensuring equipment is precisely matched to each construction scenario. In terms of power configuration, a flexible "dual-drive selectable" solution is offered. y.

For urban municipal engineering and commercial complexes with stable power supply, the motor-driven version of the pump easily passes environmental protection inspections due to its low noise and zero on-site emissions, while reducing energy consumption costs by more than 30%, achieving a win-win situation for both economy and environmental protection. Facing power shortages in southwestern mountainous highways and mining areas, the diesel-driven version, relying on its self-sufficient power system, can operate continuously for months without failure, successfully overcoming altitude differences and power supply challenges, ensuring concrete supply for critical processes such as tunnel lining and tunnel support.

Customized details showcase professional capabilities. For construction in confined tunnel spaces, a compact design with wireless remote control allows for precise pouring by a single operator. In the corrosive environment of chemical industrial parks, core components are crafted from special corrosion-resistant alloys, coupled with high-performance sealing technology to ensure stable operation even under high-intensity conditions. For multi-point indoor pouring needs, an electric propulsion system is added, significantly improving equipment relocation efficiency