We Deliver Full-Line Concrete Equipment Solutions

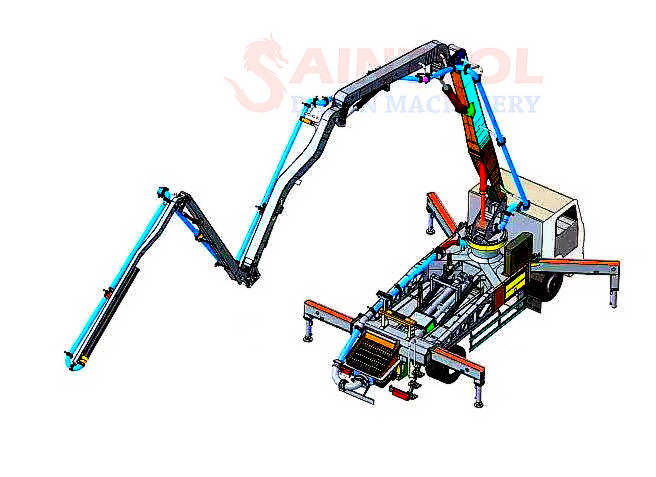

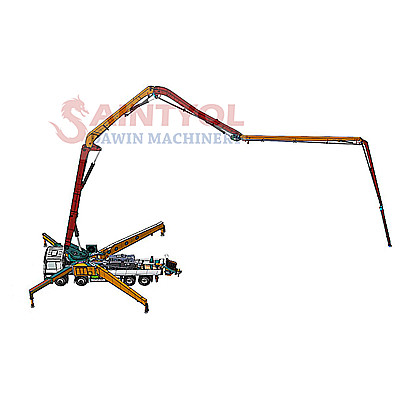

32m 5RZ Concrete Boom Pump Truck With Customized Chassis

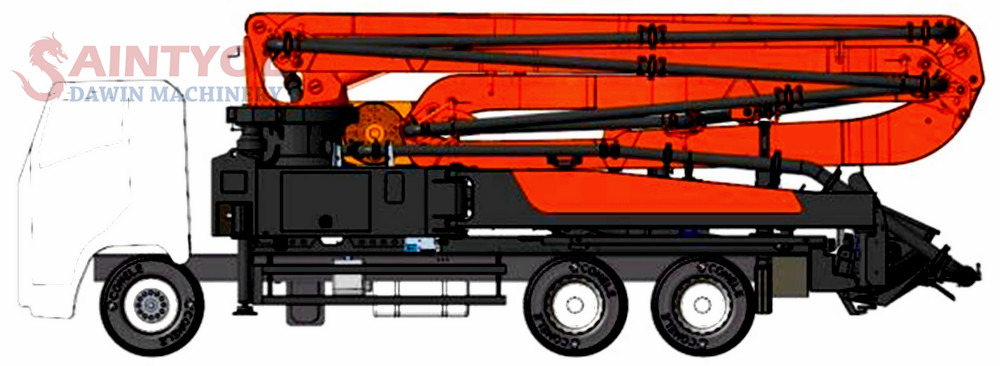

Saintyol DAWIN Machinery concrete boom pump trucks are competitive products designed by Saintyol DAWIN. it is high reliability, high efficiency, high security, high durability at an organic whole, which with reasonable matching on Chassis, power, electrical, hydraulic, pumping system. Jib structures are flexible, the trucks move easily, safe and stable.

Saintyol DAWIN Produce 30m to 63m concrete boom pump truck, full range pumping capacity and boom length to meet different meet in concrete pumping projects.CE, ISO, CCC, BV, all authorized certificates, excellent quality with favorable price, welcome contact us for detailed information.

型号 Model | 32-5RZ | ||

项目 Item | 单位 Unit | 值 Parameter | |

泵送系统 Pumping System | 最大理论输送量 Max. Theoretical Concrete Output | m3/h | 100 |

混凝土最大出口压力 Max. Theoretical Output Pressure | MPa | 7.3 | |

料斗容积 Hopper Capacity | L | 600 | |

上料高度 Feeding Height | mm | 1400 | |

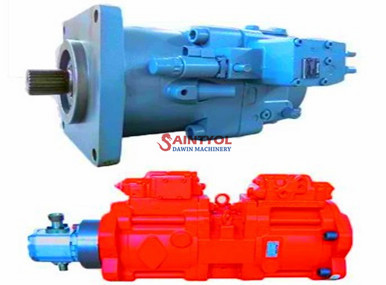

液压系统型式 Hydraulic System Mode |

| 开式 Open Loop | |

分配阀形式 Distribution Valve Mode |

| S管阀 S Valve | |

油缸缸径×行程 Oil Cylinder Diameter × Stroke | mm | Φ110×1400 | |

混凝土缸径×行程 Concrete Cylinder Diameter × Stroke | mm | φ230×1400 | |

液压油冷却 Hydraulic Oil Cooling |

| 风冷 Air Cooling | |

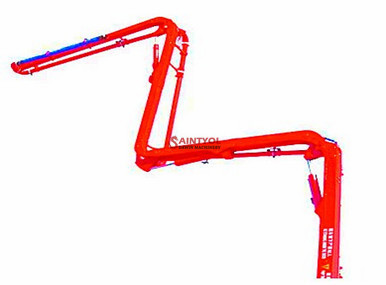

臂架 Placing Boom | 结构形式 Structure Type |

| 32-5RZ |

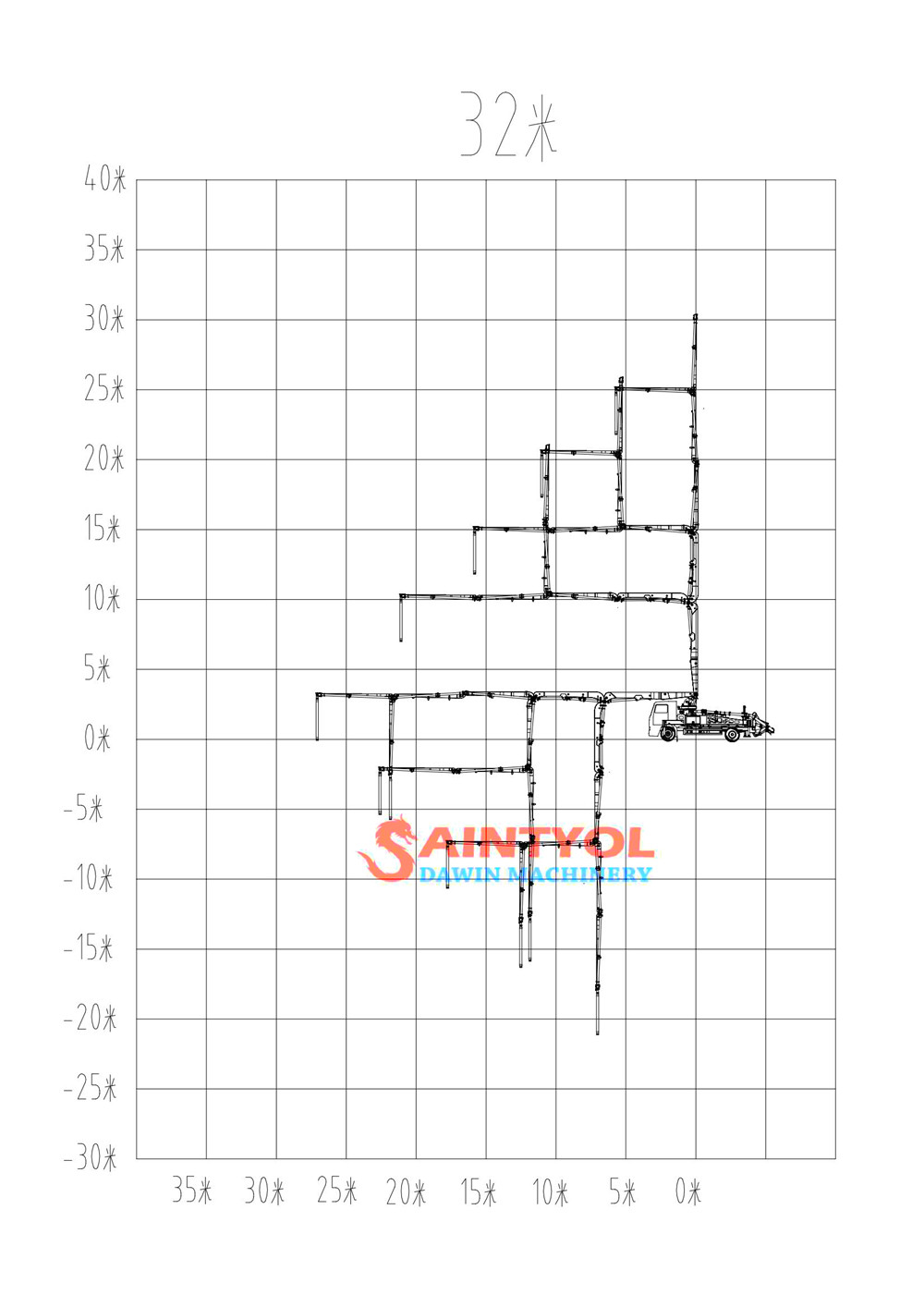

最大布料高度 Max. Placing Height | m | 32 | |

最大布料半径 Max. Placing Radius | m | 27.1 | |

回转角度 Slewing Angle |

| ±360° | |

输送管直径 Delivery Pipe Diameter | mm | 125 | |

末端软管长度 End Hose Length | mm | 3000 | |

臂架最小打开高度 Min. Height Of Opening Placing Boom | mm | 5800 | |

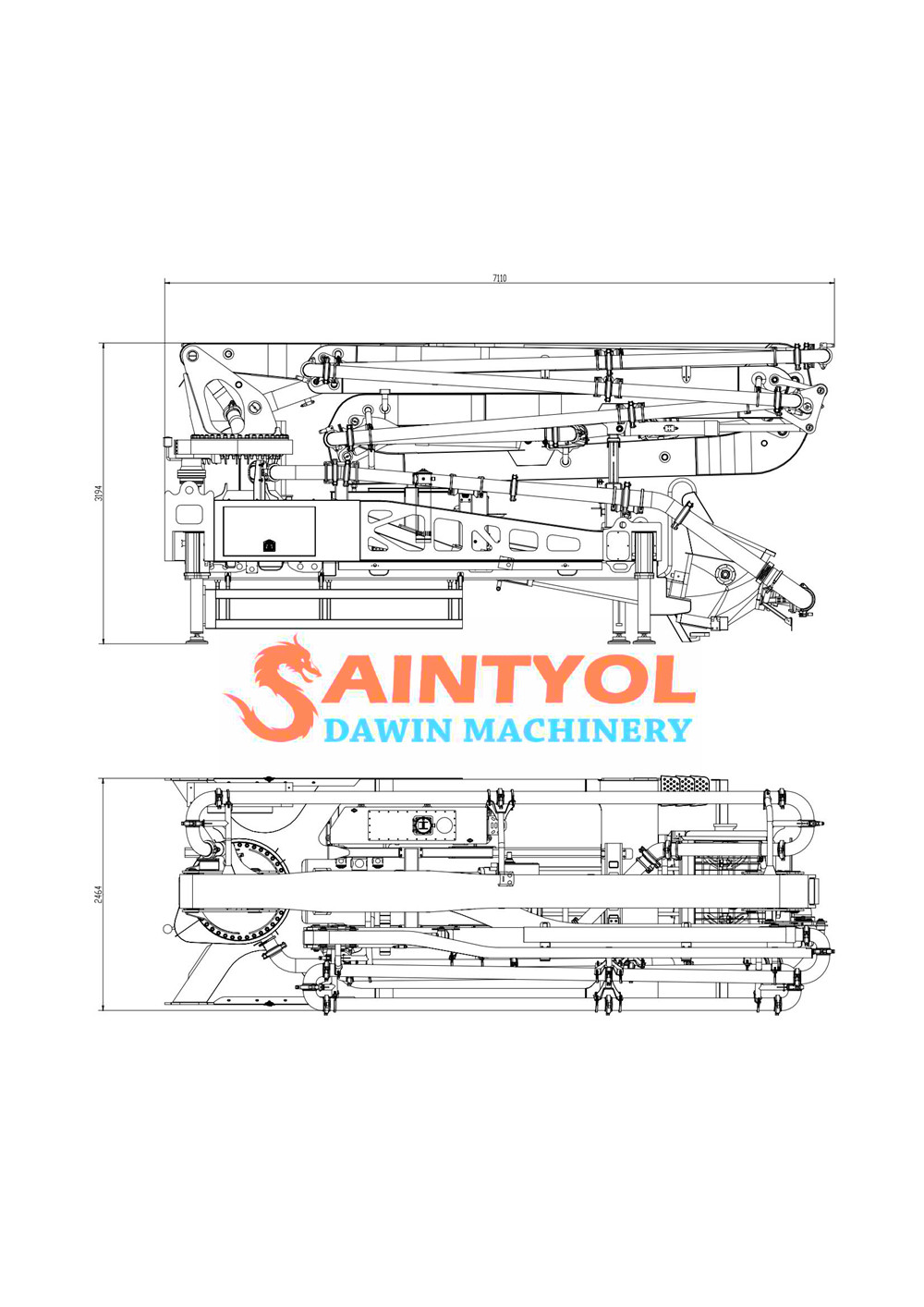

支腿跨距(前×后×纵向) Outriggers Span (Front × Rear × Side) | mm | 5950×6270×5350 | |

底盘及整车Chassis & The Whole Machine | 整车重量 Total Weight | 吨 t | 20 |

轴距 Wheelbase | mm | 4600 | |

发动机品牌 Engine Model |

| 玉柴 YUCHAI | |

发动机额定功率 Engine Rated Power | kW | 176 | |

燃油箱容积 Fuel Tank Volume | L | 300 | |

尾气排放标准 Tail Gas Exhaust Standard |

| 国VI EURO VI | |

整车外形尺寸 (长×宽×高) Overall Dimension (L x W x H) | mm | 9100x2400x3480 | |

液压油箱容积 Hydraulic Oil Tank Volume | L | 600 | |

控制方式 Control Mode |

| 手动+遥控 Manual+Remote Control | |

混凝土管清洗方式 Concrete Pipeline Cleaning Mode |

| 水洗/干洗 Water/Dry Cleaning | |

- Loading...

- Mobile Phone

- *Title

- *Content

- Name:

- Michael Liu

- Tel:

+0086-186-69798625

+0086-532-89659612

- WhatsApp:

- 8618669798625

- Address:

- Office: 216# THE 308 STATE ROAD, CHENGYANG DISTRICT, QINGDAO SHANDONG,CHINA. Factory: No.413# Tieqishan Road, Yuhuangling Industrial Park, Chengyang District, Qingdao, China

- Mobile Phone

- *Title

- *Content