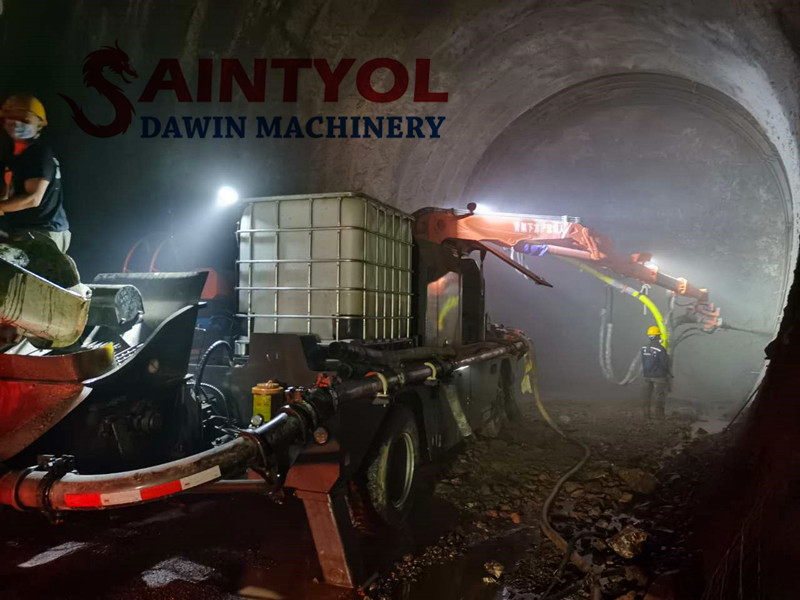

Operation method of wet concrete spray manipulator

Wet concrete spraying manipulator is a very suitable concrete spraying machine for large-scale concrete projects at present, which can effectively save human resources and construction time, especially for the places where manual spraying is difficult in tunnel projects, more and more concrete engineering projects have begun to use it. The wet spraying manipulator replaces the construction, but the manipulator construction also needs to be equipped with certain operators. How to operate the wet spraying manipulator? The following editors have sorted out the operation methods and spraying skills of the wet spraying manipulator for your reference.

1. Preparation before spraying

In order to effectively bond the sprayed concrete to the substrate, the sprayed surface should be wetted before spraying, and the loose pumice and rock slag on the sprayed surface should be removed with compressed air and water at the nozzle to ensure that the sprayed surface is clean and moist; the sprayed surface has When fissure water, the water treatment work should be done first.

2. Adjust the air volume

The air volume adjustment can directly control the flow rate of the injected concrete. In order to achieve a relatively flat injection surface and minimize the rebound, under normal wind pressure, according to the change of the slump of the injected concrete, the distance of the concrete injection and the type of surrounding rock, the air volume is passed through. knob to change the air volume. When the slump is large, the air volume is reduced, otherwise, the air volume is increased; when the spray distance is long, the air volume is increased, and vice versa; when the hard rock is sprayed, the air volume is reduced, and vice versa.

3. Adjust the spray angle

The injection angle between the nozzle and the injection rock surface is an important factor affecting the injection quality. The nozzle should always be kept at a right angle of 90 degrees to the injection rock surface layer. Adjust the injection angle at any time to ensure that the injection concrete is more densely filled into the hidden parts of the rock surface.