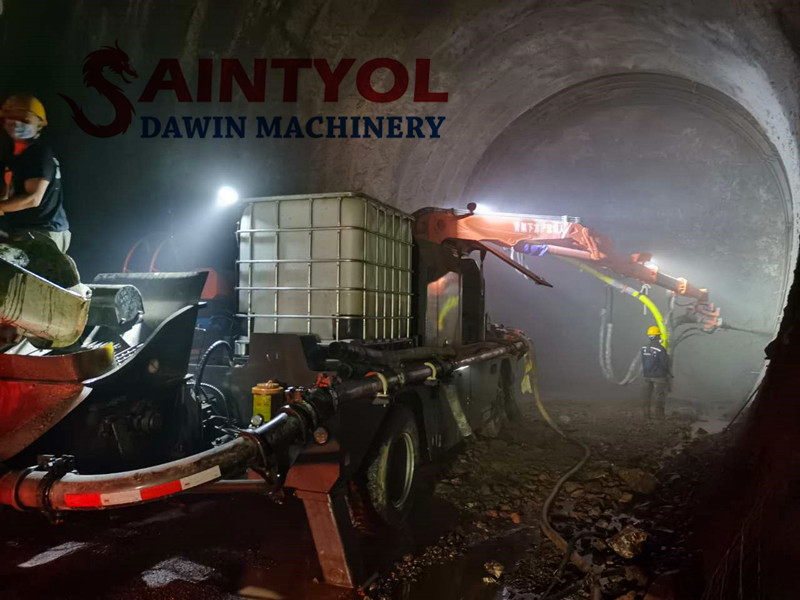

Saintyol DAWIN Machinery shares the reason why the tunnel shotcrete is sprayed down?

The general concrete spraying process is divided into dry spraying and wet spraying. For dry sprayers and small wet sprayers used for manual manual operation, the amount of rebound and drop of the spray is still very easy to control. If there is a large amount of falling, it is the problem of the ratio of sprayed concrete and the accelerator. For large wet spraying machines (manipulators), there are many reasons for falling sprayed concrete.

1. The proportion of concrete. Generally, the shotcrete is used in the mixing station to ensure the slump. The concrete will be dry and easy to block the pipe. Water is often added to the site (of course, this is not standard), but the workability must be guaranteed;

2. The method of the operator. The operator's technique and familiarity with the machine largely determine the rebound and fall of the concrete, because he will adjust the wind pressure, the size of the discharge, the spray angle, the rotation of the nozzle, the dosage of the accelerator, and the The working environment and mood are also very important;

3. The quality of the accelerator.

4. The dust pollution on the secondary spray layer and the surface of the steel frame is not cleaned thoroughly, which reduces the bonding force of the old and new concrete;

5. The shotcrete is not dense and hollow, causing water leakage on the initial support surface and corrosion on the surface of the steel frame;

6. Combining the above two reasons, before the entire initial support is not stable, it is caused by convergence and settlement, resulting in the exposed steel frame and the drop of the concrete surface; The loess has not been cleaned thoroughly.

2. Prevention and control measures:

① The surface of the steel frame and the shotcrete must be thoroughly cleaned. (For loess tunnels, water washing is strictly prohibited);

② When spraying, the spraying hand first sprays the back of the stuffing steel frame, and then sprays in layers with a thickness of 3-5cm per layer. For water-rich tunnels, try to take measures to reduce the long-term erosion of concrete by the accumulated water behind the initial support;

③ Short footage, strong support, early closure, and quick loop formation reduce disturbance to the original soil layer and reduce the exposure time of the original deeply buried soil layer; Except clean up.