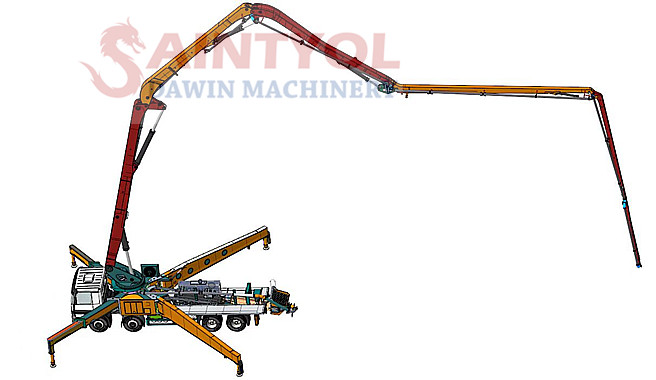

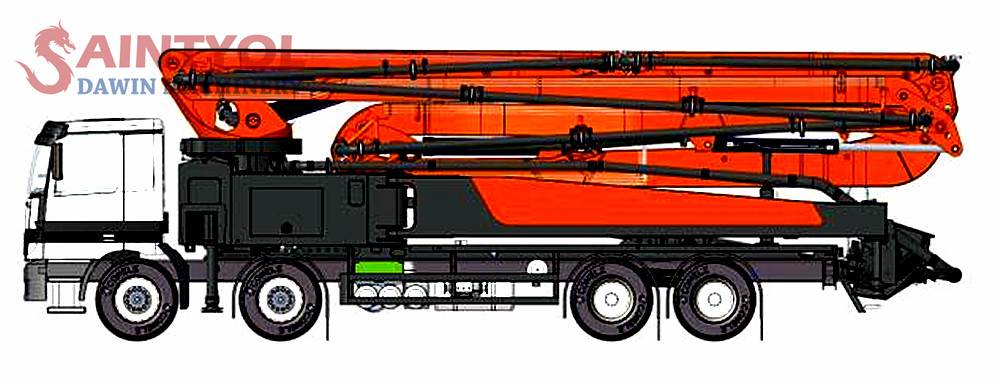

52m 6RZ Boom Concrete Pump Truck With Customized Chassis

Saintyol DAWIN Machinery boom concrete pump trucks are competitive products designed by Saintyol DAWIN. it is high reliability, high efficiency, high security, high durability at an organic whole, which with reasonable matching on Chassis, power, electrical, hydraulic, pumping system. Jib structures are flexible, the trucks move easily, safe and stable.

Saintyol DAWIN Produce 30m to 63m concrete boom pump truck, full range pumping capacity and boom length to meet different meet in concrete pumping projects.CE, ISO, CCC, BV, all authorized certificates, excellent quality with favorable price, welcome contact us for detailed information.

Model | 52-6RZ | ||

Item | Unit | Parameter | |

Pumping System | Max. Theoretical Concrete Output | m3/h | 170 |

Max. Theoretical Output Pressure | MPa | 10 | |

Rated Working Pressure | MPa | 32 | |

Hopper Capacity | L | 600 | |

Feeding Height | mm | 1480 | |

Hydraulic System Mode |

| Open Loop | |

Distribution Valve Mode |

| S Valve | |

Oil Cylinder Diameter × Stroke | mm | Φ140×2100 | |

Concrete Cylinder Diameter × Stroke | mm | φ260×2100 | |

Hydraulic Oil Cooling |

| Air Cooling | |

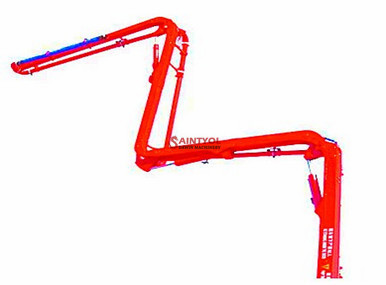

Placing Boom | Structure Type |

| 52-6RZ |

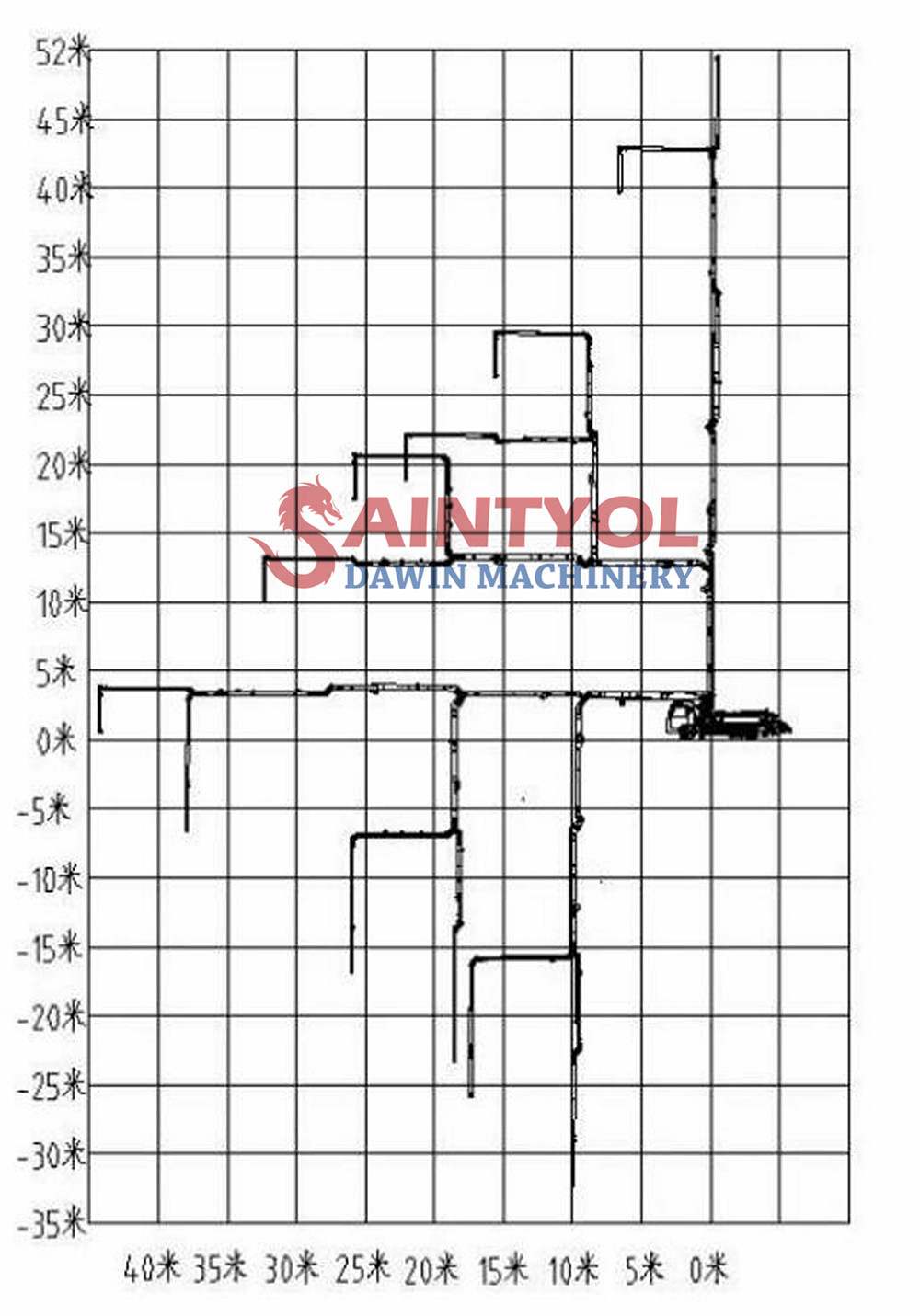

Max. Placing Height | m | 51.4 | |

Max. Placing Radius | m | 46.4 | |

| Max. Placing Depth | m |

36.9 |

Slewing Angle |

| ± 360° | |

Delivery Pipe Diameter | mm | 125 | |

End Hose Length | mm | 3000 | |

Min. Height of Opening the whole Booms | mm | 8000 | |

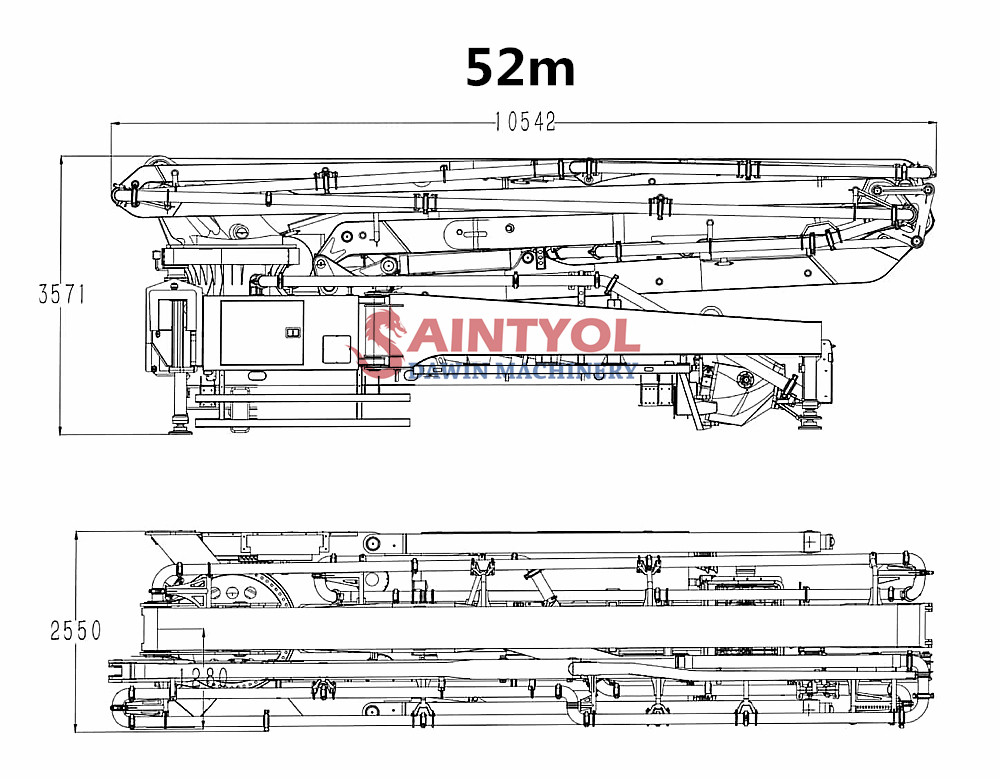

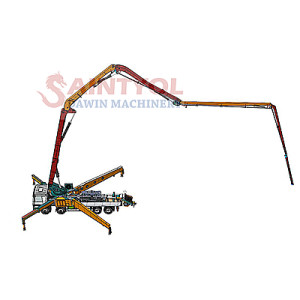

Legs Span (Front x Rear x Longitudinal) | mm | 9650x 10150x9820 | |

Wheelbase | mm | 1950+4500+1400 | |

Engine Power | KW | ≥323 | |

Overall Dimension (L x W x H) |

mm |

12680x2550x4000 | |

Hydraulic Oil Tank Volume | L | 600 | |

Control Mode |

| Manual+Remote Control | |

High Pressure Water Pump Pressure | MPa | 7 | |

Concrete Pipeline Cleaning Mode |

| Water/Dry Cleaning | |

- Tel

- *Title

- *Content

Don't forget to sign up!

Find out early about all upcoming promotions and

newproducts releases

- Name:

- Michael Liu

- Tel:

0086-186-69798625

0086-532-89659612

- WhatsApp:

- https://wa.me/8618669798625

- Address:

- Office: 216# THE 308 STATE ROAD, CHENGYANG DISTRICT, QINGDAO SHANDONG,CHINA. Factory: No.413# Tieqishan Road, Yuhuangling Industrial Park, Chengyang District, Qingdao, China