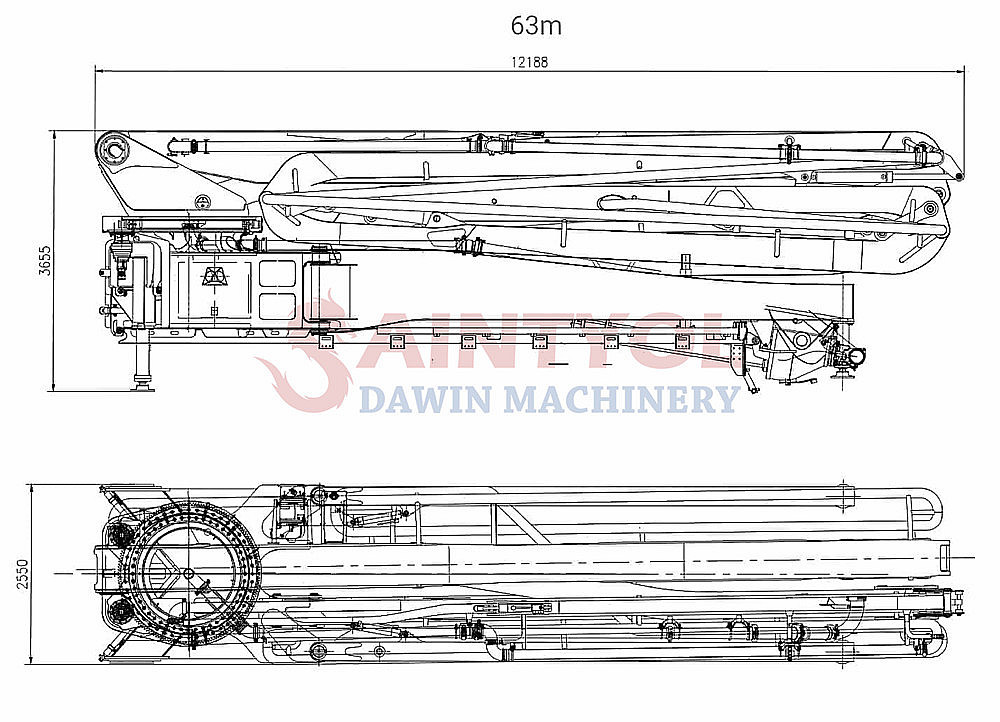

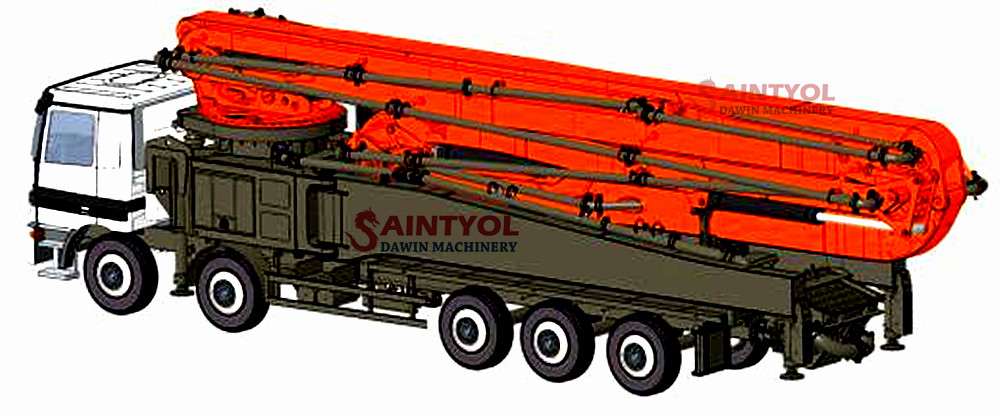

62M 6RZ BOOM CONCRETE PUMP TRUCK (ISUZU 8*4 Chassis)

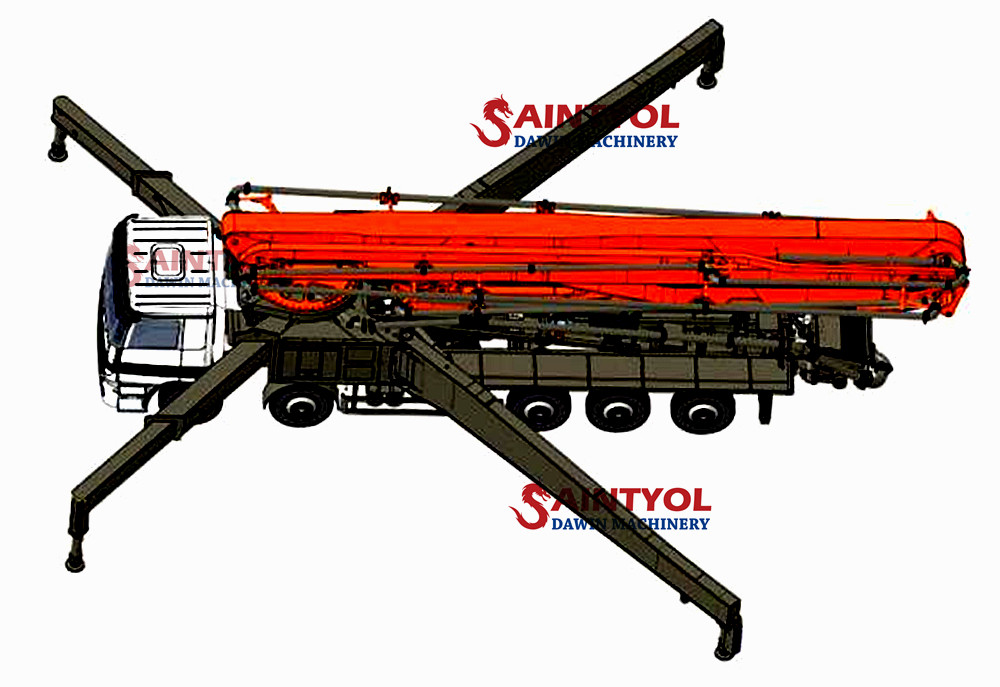

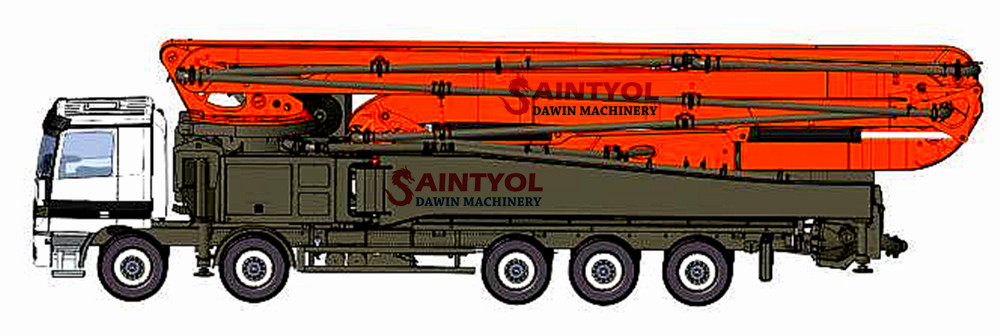

1. The 62m Pump Truck is OEM for foreign customers, with X Type Retractable Leg two legs, total weight is about 49 tons. In China, we are 8x4 chassis 62m pump truck. The 62m pump truck with 8x4 chassis is reliable after practice in China Job-site, two level front legs are flexible and convenient to use. For large pump truck, our Saintyol DAWIN brand has our own excellent technology in the pumping system and electrical control system, we recommend you to purchase the whole pumpcrete without chassis. Our pump can match your local chassis. We have our own technology on the boom system and pumping system.

2. The pumping pressure is adjusted step-less, without high and low pressure switching, the max. Outlet pressure is 10MPa, the pumping ability is strong, and no material picking.

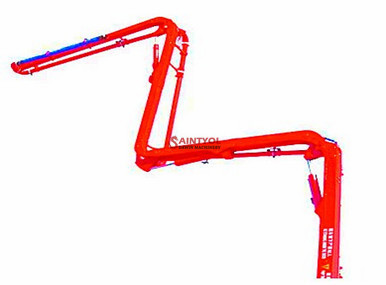

3. The boom system has active vibration reduction technology, stable construction.

Model | 62X-6RZ | ||

Item | Unit | Parameter | |

Pumping System | Max. Theoretical Concrete Output | m3/h | 170 |

Max. Theoretical Output Pressure | MPa | 10 | |

Hopper Capacity | L | 600 | |

Feeding Height | mm | 1450 | |

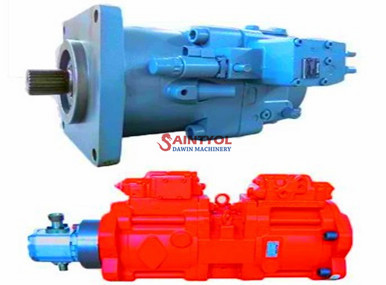

Hydraulic System Mode |

| Open Loop | |

Distribution Valve Mode |

| S Valve | |

Concrete Cylinder Diameter × Stroke | mm | φ260×2100 | |

Hydraulic Oil Cooling |

| Air Cooling | |

Max. Aggregate Dimension | mm | 40 | |

Placing Boom | Structure Type |

| 62-6RZ |

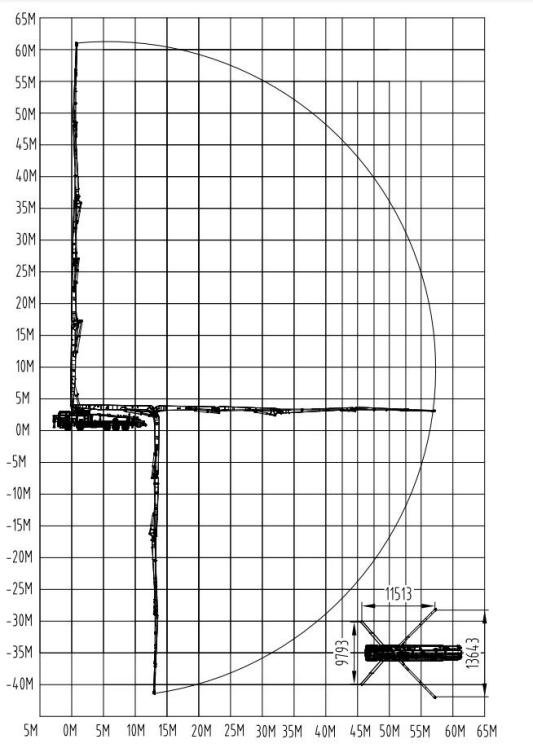

Max. Placing Height | m | 61. 1 | |

Max. Placing Radius | m | 56 | |

Slewing Angle |

| ± 360° | |

- Tel

- *Title

- *Content

Don't forget to sign up!

Find out early about all upcoming promotions and

newproducts releases

- Name:

- Michael Liu

- Tel:

0086-186-69798625

0086-532-89659612

- WhatsApp:

- https://wa.me/8618669798625

- Address:

- Office: 216# THE 308 STATE ROAD, CHENGYANG DISTRICT, QINGDAO SHANDONG,CHINA. Factory: No.413# Tieqishan Road, Yuhuangling Industrial Park, Chengyang District, Qingdao, China